Industry Write-ups

WARPAGE IN ROTO MOULDING PRODUCT

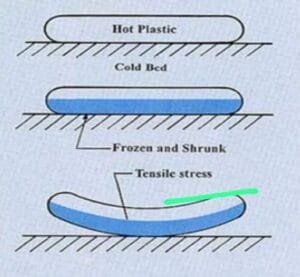

Warpage commonly occurs in roto moulded parts due to the nature of the process, i.e., cooling from one side of the plastic only. The effect is easily demonstrated. Imagine a “pancake” of hot plastic placed on a flat, cold surface. The bottom surface will cool rapidly and have little crystallinity. The top half will, however, cool more slowly because the lower layer insulates it from the cold metal. The top half will therefore contain a higher degree of crystallinity and will shrink more than the bottom half as it cools. This will cause tensile stress at the interface, which will result in warpage of the plastic as illustrated in Figure

As a general rule, therefore, warped sections will curve towards the cooler surface. To alleviate this effect during rotational moulding, it would be desirable to cool the inner and outer surfaces of the plastic at the same rates. If this cannot be achieved, then it is preferable not to cool the metal mould too quickly because the inner surface will only be cooling slowly. As a further measure to avoid warpage, thick and thin sections should be avoided in the moulding. Thick sections will cool slower and be more crystalline. In achieving this state, the thick sections will tend to pull material from the thin areas and this causes warpage/distortion in the final product. This can also occur if there are hot spots or cold pots on the mould. As a final point, it is also worth noting that any use of jigs to remove warpage or reduce shrinkage will set up residual stress in the plastic. This is because the plastic is prevented from taking up the natural configuration which its structure prefers. When stresses are moulded into a product or introduced shortly after moulding using jigs, the material will become more susceptible to environmental stress cracking (ESC).

– Written by FAKHRUDDIN ALI AHMED, Director of Polyconnect Bharat LLP.

Connecting people, ideas, and solutions to drive your industry forward with POLYCONNECT Bharat

Company

About Us

Events

Support

Services

Contact

Info@polyconnectbharat.com

+91 8171154544

PLOT N0. MIG-A-160, SHASTRIPURAM, AGRA (U.P) PIN CODE-282007, INDIA

©2024 All Rights Reserved, POLYCONNECT BHARAT