Industry Write-ups

WHICH ROTATION DIRECTION OF COUNTER ROTATING TWIN SCREWS FOR UPVC IS APPROPRIATE?

Objectives of twin-screw Extruders are to get –

A long production run of UPVC product be it pipe, profile, or sheet,

Of best quality,

With minimum thickness variation,

At minimum cost, and

Minimum wear & tear of screw & barrel

Twin screw extruders have two intermeshing counter rotating identical screws encased in a matching barrel.

Screw & barrel can be parallel or conical.

They work like a positive displacement pump, independent of frictional criterion.

During twin screw extrusion – PVC is conveyed, compressed, de-gassed, plasticated, sheared, Kneaded, fused at optimum level and homogenized before it enters the die.

Which direction of rotation in counter rotating screws is appropriate?

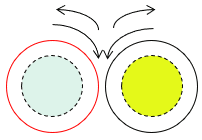

In counter rotating screws, there are two possibilities when viewed from the top –

1. The screws can rotate towards the centre,

2. The screws can rotate towards the sides.

In either case, material will move forward.

Let us consider the pros and cons:

Case 1 – Screws rotating towards the centre:

Inward direction of rotation may pull the material from the hopper into the bite of the screws more effectively.

However, there is always a danger that a foreign object is pulled into the screws causing damage.

This aspect suggests that the screws rotating away from the centre are preferred.

However, there is a technical consideration for counter rotating screws moving towards the sides.

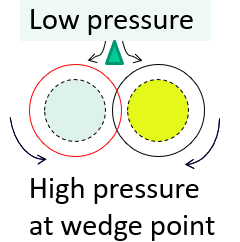

Screws rotating towards the sides are more popular because –

It is easier to fill the screws channels completely as the material is pulled down the sides to fill the bottom.

This builds up high pressure region at the wedge point at the bottom of the screw and low-pressure region at the top region of the screws.

This low-pressure region at the top creates a favourable condition for venting the gases in the degassing section (de compression zone).

Material is not forced through the vent, and it is easier to de-gas the milled fraction of material that passes through the gaps between the screws and remove HCl, moisture, air, volatile matters etc.

Such dispersed and degassed material pushed upward due high pressure at the bottom of the screws aided by the flanks of counter rotating screw provides milling and mixing action to entire PVC compound, increment by increment.

If understood and utilized properly, this arrangement provides gentle processing to PVC in twin screw extruders.

– Written by

Mr. Yashodhan V. Kanade

PVC Technologist and Performance Improvement Consultant